The role of an engineer in traditional agricultural farming is to design and develop new processes, systems and products. In Ag-tech the fundamentals are no different but when you’re working on commercial farming projects for indoor operations, there are many other factors and challenges that come into play.

ZipGrow is and has always been a full-service company from the design and engineering of products and farm builds, through to implementation of those builds and customer service beyond.

Devin Lamb heads the engineering department here at ZipGrow and explains that the department is constantly developing and evolving.

On any given day the engineering department could be working on a rendering or re-design for a commercial hydroponic farm build, or they could be modeling and 3D printing a new product in development.

They drink lots of coffee, have messy desks and scratch their heads, a lot!

But in all seriousness, what actually goes on at ZipGrow and what does an ag-tech engineer do?

At ZipGrow Inc. there are two main sides of the business – product development for commercial use, and design for home hobbyists. Then there’s also commercial farms and greenhouse operations, where the team works directly with entrepreneurs and business owners to design and build a custom indoor system that will best fit their needs.

Commercial builds

Clients coming to ZipGrow seeking expertise to build an indoor farm operation usually have the same goal, to provide better food solutions for their community or region that they live in. But that’s quite often the only commonality. They all live in different areas; from extremely remote to ultra-urban.

Some clients come with knowledge in engineering such as Benjamin Feagin Jr. of Agri-Tech North. Others have a vision and an end goal, but have no knowledge of how to achieve it or any formal background in technology or farming. Add in budgets and workable space or, in many cases, no space yet, and the ZipGrow team will take all of those considerations on board.

ZipFarm™ systems and ZipGrow Greenhouse bundles are scalable, allowing farm designs to be designed with room for growth – quite literally!

The buildings however are not one size fits all and the engineering team works closely with the client and their space to make sure that the installation maximizes efficiency.

“One of the biggest challenges,” explains Devin, “is that a building is never exactly the way that the plans say it is.” Custom Vertical farm builds

are typically built in previously abandoned buildings such as old warehouses, repurposed community buildings or other commercial spaces designed for retail or offices. “Except for greenhouses, we have never developed a commercial indoor vertical farm in a building that was purposely built to be a farm.”

Clients are connected to the engineering department through sales and business development and the preliminary stages look at the building size, floor plan and ceiling clearance.

The next stage is where it gets more detailed with considerations for pillars, clearance and any modifications that may need to be made to the building such as new walls.

Sarah Grenier is a co-op student at ZipGrow, currently in her 3rd year of studies of a four year biomedical and mechanical engineering degree at Carleton University.

A large part of her role is to take the specs from sales and configure, and then reconfigure design plans to make the most optimal use of space while also taking into consideration HVAC, electrical and plumbing.

In some circumstances, ZipGrow will communicate with engineers at the site of the project to ensure that requirements are accurate.

ZipGrow also develops and installs systems for greenhouses, but as Sarah points out “even with a greenhouse, there are challenges posed. Some greenhouses have pillars or ceiling trusses to work around and it can get very complicated”.

The designs and renders are created on specialized software and fine tuned with accuracy.

Christophe Assi is another young engineer in training at ZipGrow, brought in on an internship with a Bachelor’s Degree in Mechanical Engineering. He also assists with design from product through to farm build and enjoys the variety of challenges that the job requires “because we offer a full service and do so much in house, including HVAC, electricity and the actual hydroponic systems I get the opportunity to learn about the entire process.”

Whether you are building a small or large scale controlled environment agricultural business there are core applications that need to be considered, such as layout and workflow. ZipGrow guides the new farmer through these steps from the offset, all the way through to the farm build where members of the engineering team are on site. Having the ZipGrow team involved in the final build eliminates issues since they have been involved from inception.

Give them a problem, they’ll find a solution.

Every design build has been different and over time the team has learned many lessons and developed knowledge and expertise from previous challenges and obstacles that have arisen. How they overcome it and how it is also what makes their job interesting, and there are many lightbulb moments along the way!

Devin grew up on a traditional agricultural farm and went to school for electrical engineering.

He has decades of experience in custom woodworking, inventing jigs to make life easier. “Growing up on a farm I was constantly improvising and engineering solutions to things to be able to fix them myself. “

The same can be said at ZipGrow not only for farm builds but also for designing new innovations, many of which were created to fill a need for our customers. The team will tinker and tailor, tweak and define until it’s done right.

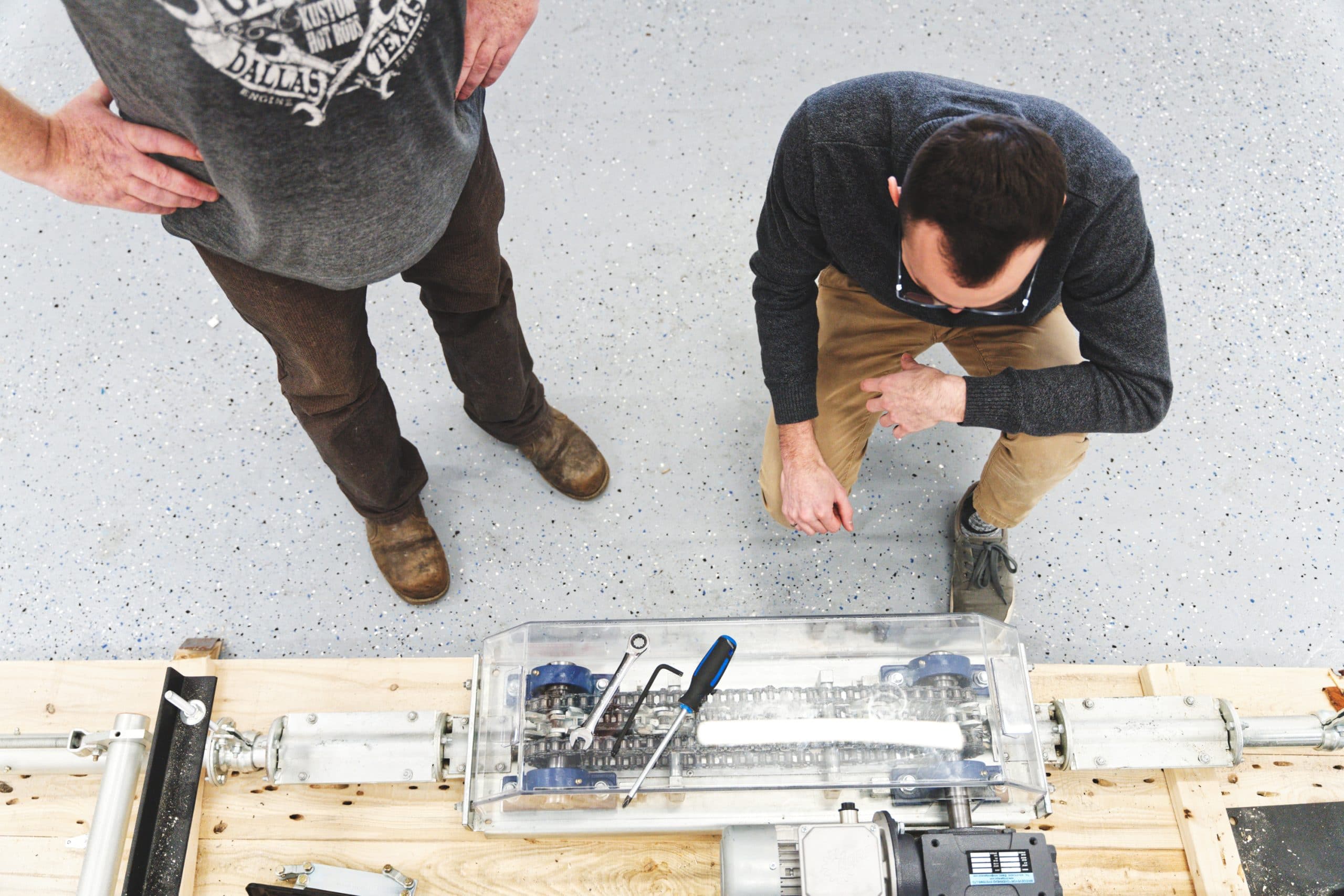

Devin and Chris have recently been working on bringing a new greenhouse rack to market.

From sourcing affordable parts to constructing a design that will provide easy assembly for the user “We developed a prototype with many iterations along the way”, explains Christophe. “The final product was the 5th or 6th concept from the original idea.”

While the engineering team doesn’t always agree in the office on what playlist to listen to, they all agree that working in ag-tech gives them a lot of variety within a day that touches across all aspects of engineering from mechanical, to electrical and agricultural.

If you are interested to learn more or start planning your own vertical farm? You can find out more about some of the farmers using ZipGrow technology along with details about indoor ZipFarm™ efficiencies and opportunities on our website or by reaching out to our sales team. [email protected].