The word “sustainability” has become synonymous with vertical farming and Controlled Environment Agriculture (CEA) due to claims of reduced water consumption, increased local production, and reduced use of pesticides needed to grow high-quality produce. Many assume that vertical farming is an inherently sustainable method of production because of these specific benefits. However, we at ZipGrow Inc believe the true meaning of sustainability is both environmental and economic, and we foster sustainability by taking a “cradle to grave” approach with the products we use to grow some of the best quality produce in the world. When we say “cradle to grave” what we mean is an assessment of both the environmental impact as well as the profitability of using any inputs (such as fertilizer, water, consumables) and permanent equipment from initial manufacturing all the way to final recycling or repurposing of the product.

This way of approaching sustainability is beneficial not only to the farmers and environment of today, but also those of the future, all while maintaining a profitable and scalable business model.

Hydroponic systems are defined as growing systems that use a nutrient solution instead of soil to support root growth and plant development. Although the primary delivery method of nutrients and beneficial organisms to the plant occurs via nutrient solution, there quite often is a non-soil substrate used to support the crop architecture as well as support beneficial microbes that are essential to crop health.

These substrates can either be made of organic materials such as clay, sand, gravel, coco, peat, perlite, or vermiculite (the latter two being mined minerals that undergo processing), or synthetically produced such as Mineral Wool, Engineered Foam, or Matrix Media™. While it may seem as though organic or natural substrates are the best option, there are many factors to consider when evaluating the environmental and financial impact of the substrate you might use:

Mass and Density

Heavy minerals such as sand and gravel are great on a small scale but transporting and handling these materials for reuse is simply not feasible. There are also challenges with proper oxygen access and root compaction over a certain volume of these substrates, making them a less than optimal solution for commercial hydroponic growers.

Synthetic options such as Mineral Wool, Matrix Media™, or Engineered Foam products are superior in this regard, as they have significantly less mass than solid minerals while offering a very consistent density which supports uniform and healthy root development.

Manufacturing Processes or Sourcing

Organic or natural substrates often have the appeal of being sustainable due to their degradation in the environment and clean production methods. This can sometimes be misleading though; as the demand for these products increases there is ongoing debate about how sustainable these products and their manufacturing processes are. Products such as peat are increasingly coming under scrutiny due to concern over bogs and wetlands being potentially irreversibly harmed during peat harvesting. Though peat can regenerate 60% faster than it is currently harvested in North America, the demand for peat is rising, resulting in nearly 30,000 hectares of land to be affected by peat production in Canada alone (CSPM 2015). Mineral wool, which has become synonymous with the brand name Rockwool, has become increasingly popular in recent years due to its affordability on a large scale, as well as production methods which are minimally intrusive to the environment.

Affordability of this substrate is one of the major reasons why it is the primary substrate used in greenhouse tomato, pepper, and cucumber production. However, it is important to note that to manufacture mineral wool, temperatures of over 1600°C are needed, requiring a significant energy input. An alternative to peat or mineral wool is the use of coconut fiber substrates, which are minimally intrusive to manufacture and a seemingly infinite resource in the sense that coconut is cultivated in many parts of the world and is a by-product of many coconut food products. The only major environmental concern with coconut substrate is that production is rarely centred near the major greenhouse hydroponic producers of North America, meaning significant environmental and financial costs are incurred transporting these products northward.

Recycling, Degradation and Repurposing

Substrates such as peat and coco derived from non-mineral natural sources have the benefit of being biodegradable and can be easily handled on-site or at municipal compost facilities to be repurposed into fertile soil amendments after production. Mineral substrates such as perlite, vermiculite and clay can be reused a handful of times but break down into debris or particles that are unsuitable for hydroponics after 2-3 crops, creating clean fill that is difficult to handle on a large scale, though usually clean enough for integration into soil rehabilitation projects.

Mineral wool substrates can be recycled, and significant investments into recycling facilities to handle mineral wool has been made in recent years, however proximity to these recycling facilities is the primary limitation to mineral wool reuse. Unfortunately, there is still a significant amount of mineral wool growing slabs that end up in landfill sites. Nevertheless, mineral wool still offers some of the best economic and environmental benefit to vining crops such as tomatoes, peppers, and cucumbers in hydroponics.

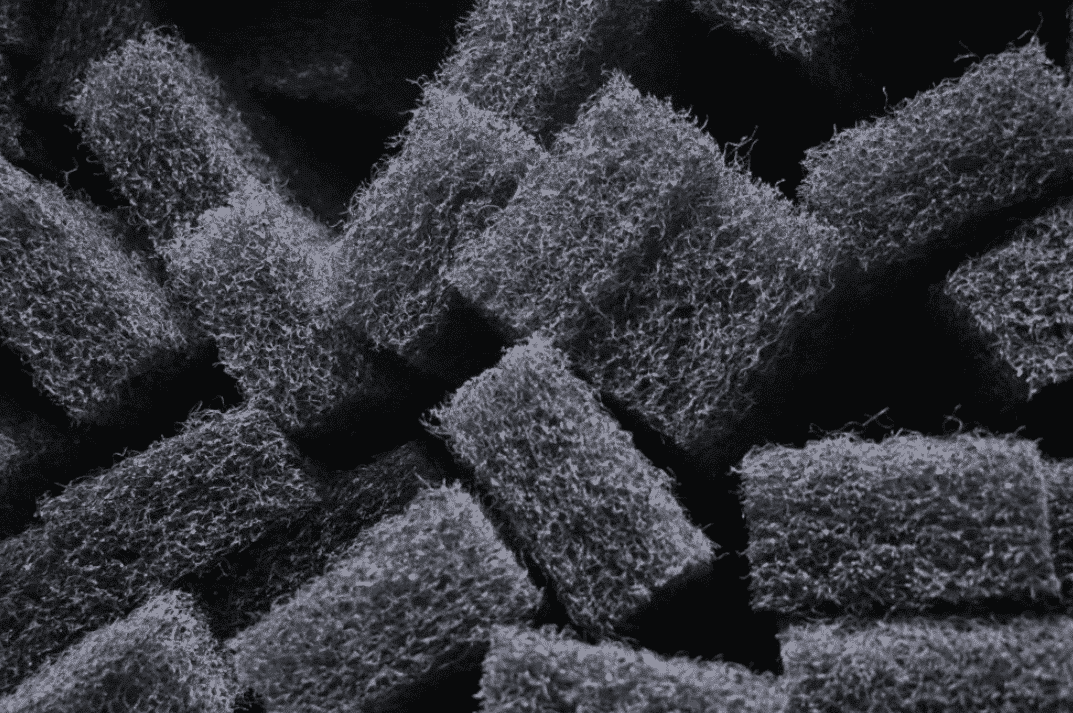

Engineered Foam products that are biodegradable such as certain Oasis Cubes and GROWFOAM® plugs offer sustainable production practices while still being lightweight for transportation, as well as biodegradable. Synthetic substrates such as Matrix Media™ offer true reusability in the sense that the substrate is washed and disinfected to be completely reused for each crop cycle indefinitely.

The ZipGrow Way

At ZipGrow, we have evaluated substrates extensively and succeeded at developing a system which we believe truly encompasses environmental and economic sustainability.

Our Matrix Media™ is made of 100% recycled plastics, diverting significant waste from landfills. It is also extensively reusable, though we haven’t determined a lifespan on this product, we have farms that have been using this media for 9 years with only the odd replacement needed because of wear and tear. PET-1 is one of the few plastics that can be recycled repeatedly without a significant decrease in quality (PETRA 2015). This gives us the advantage of reduced operating costs associated with purchasing a media for the plants, while also diverting considerable waste from landfills and the environment. Though substrate-free systems such as aeroponics require even less inputs there is a limitation regarding BSA (Biological Surface Area) and the ability to culture beneficial microbes on the substrate surface. https://www.youtube.com/embed/qsL3W-xuLII?feature=oembed

Choosing a media that will fit your system is important as it will determine the health of your plants, fish, and microbes. Although we have our favorite media chosen already, we experimented with many media before choosing Matrix Media™ and compared various factors of each.

Earth day 2022 is on April 22nd. Post in comments how you are making small changes to make a difference. Happy Growing!