Water is Life

With water being the main component in hydroponics, the quality of it is incredibly important.

Many people assume that if you are on a municipal water supply, you can just add your nutrients, and you’re good to go; in some cases, that can be true. However, some things in municipal water or your well water may need to be accounted for.

While we are not water quality experts (being a science of its own), this blog focuses on the basics of quality in terms of best cases and operations for hydroponic growing both on a hobbyist and commercial scale.

Water quality has a lot to do with the performance of your crop. Quite often, we hear about deficiencies in crops from customers or farmers, and it’s seldom an actual lack of nutrients but almost always the availability of nutrients to the plant. The water quality will affect the uptake of nutrients by the plant. Hard water (water that has high mineral content), is an excellent example of this. If your city has hard water or you are on a well system, it can really restrict the availability of nutrients to your plants.

Growing in soil v’s hydroponics

When growing in soil, all the critical nutrients and minerals are bound to soil through a charge; plants send out lateral fibrous roots when they encounter these nutrients and want to take them up. They release H+ and OH- ions that balance out the charge and help release that mineral to the plant. The plant can take these minerals up, and move them across root membranes, releasing the mineral from the soil.

In hydroponics, it’s different because we don’t have all that soil holding these nutrients close to the root, and the plant is not constantly searching for nutrients because water is always moving and available. We need to ensure that these nutrients are highly available throughout the water solution because there is no solid holding them by the roots. The ion exchange doesn’t really happen in the same way; it’s not unlocking it from a soil particle that’s negatively charged, but taking up nutrients that are delivered via solution. Hydroponic crops still release ions (this is why pH changes!) but not in the same way as they would in solid. So to replace that in hydroponics, we constantly supply nutrients to the root zone in solution.

Not all water is equal.

Because all the nutrients are being delivered via solution, the incoming water quality is essential and something you must always consider.

Reverse Osmosis (RO) Systems

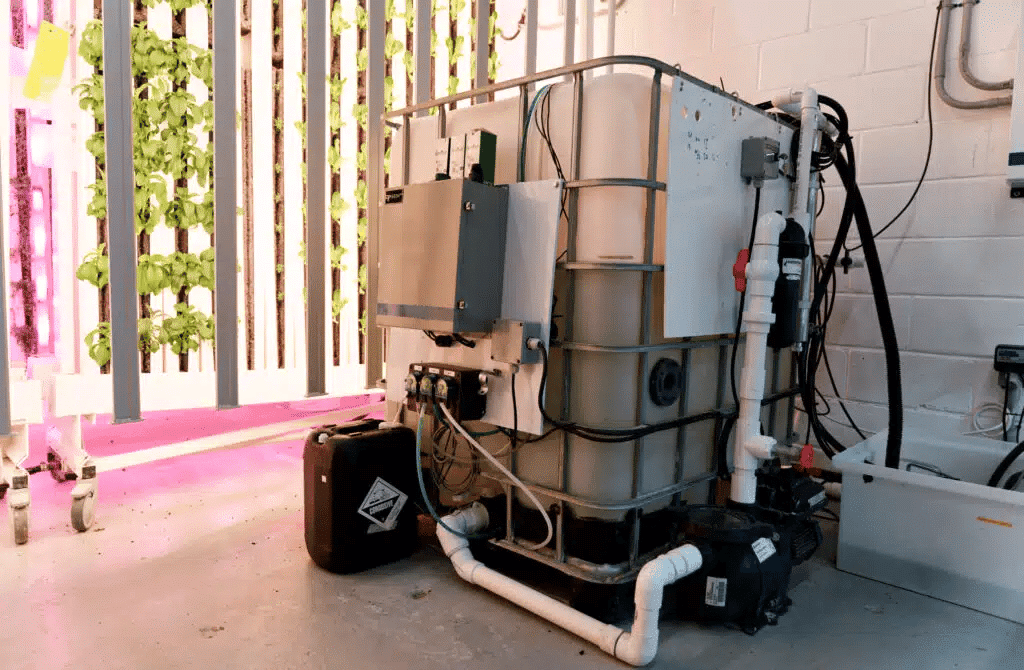

In any hydroponic system, it will make your life a lot easier if you have a reverse osmosis system that supplies your base water. RO systems come in various sizes depending on the size of your operation. They are a series of filters that remove larger particles and those that can’t be seen. This multi-stage process pushes the water through a specialized, semipermeable membrane. The results of which are water that’s as close to zero EC level as you can get, typically around 0.1 EC or less.

Municipal water can come in at up to 0.6-0.8 EC, so if you are adding in nutrients on top of that (without taking into account the original EC levels), you may be providing more nutrients than needed and could be harming your plants.

RO systems can be relatively inexpensive for home use, through to costly systems for larger operations. In our experiences, many of the folks who spend months struggling with pH, and artificially trying to lower it, reached the point where looking back, they wish they’d just installed an RO filter and avoided the cost and headache of fighting the fundamental chemistry of their system.

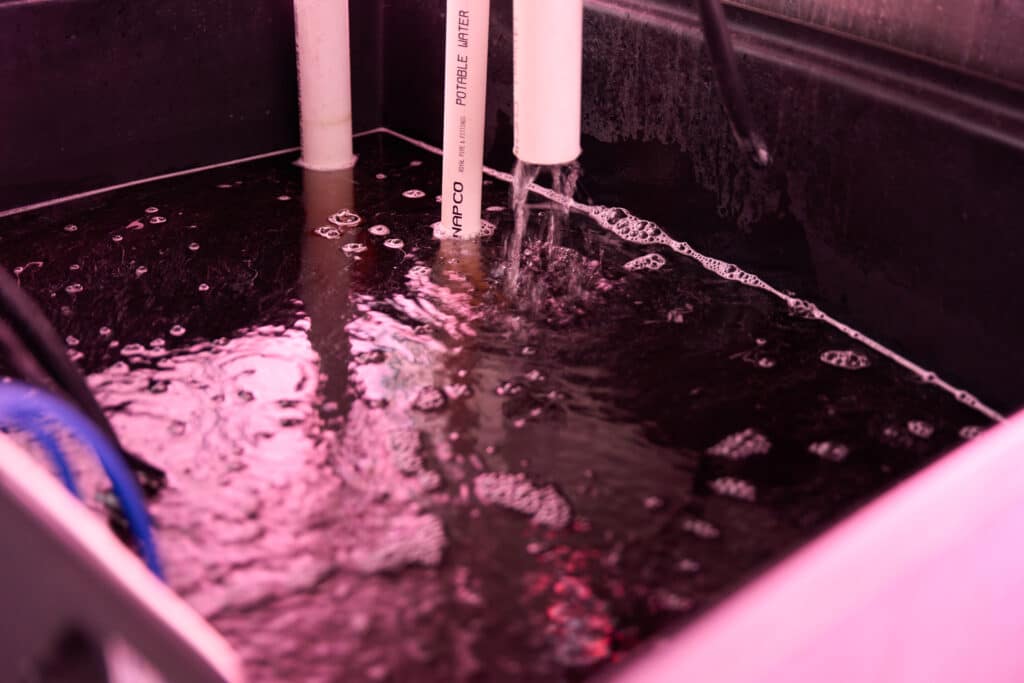

An RO system can be slow to process the water, so we advise that people have a separate reservoir/tank so you have plenty of pre-filtered water when you need it.

What’s in the water? Knowing your municipal water quality.

Knowing the quality of your existing water supply is a good idea. You can send your water off for lab testing; many local universities will offer that as a paid service. They will give you a full breakdown to know your carbonates, any heavy metals present, and the pH of your incoming water. Especially for commercial growing, you would want to get a professional water panel done. It’s an inexpensive way of making sure everything is safe. Information is often generally available too within your own municipality.

Let it rain…or should you?

For sustainability reasons, many hydroponic growers will consider using rainwater in their tank. This can work well, but you need to be conscious that rainwater tends to be pretty acidic; it may also carry diseases, parasites, or pathogens. If you use rainwater for your hydroponic systems, there is a high risk of things like root crop diseases and fungal and bacterial diseases, and algae. It’s a good idea to have a disinfection plan or water filtration process like an RO system.

Water temperature

Basic concepts that apply in traditional growing in terms of water temperature also apply in hydroponic growing; too low, and you will shock your plants; too high, you create an environment perfect for algae, bacteria, and many diseases.

You would want to curb that environment because once those things get into your system, it’s impossible to get them out without a full system shutdown to scrub everything out.

A general rule of thumb for a hobby grower and even some commercial growers is that your water temperature should be a couple of degrees colder than your air temperature. Usually, this is easy to maintain without much effort.

Tips on maintaining your water temperature:

- Air Stones - You should be aerating your water anyway, but they help oxygenate it too.

- Chillers - Typically used for aquariums, can be very effective in aquaponics and hydroponics. Dozens of companies sell chillers of various sizes, which are more common in larger systems.

- Go Big - A larger volume of water always helps as it provides a bigger buffer. More water circulating in your system than in your reservoir means all that water is heating up faster than the water supply.

- Cover Up - If you are growing hydroponically outdoors, you want to keep things in the shade or insulate your reservoir with a cover.

A simple tip for quickly bringing down your water temperature is to fill large milk jugs with water, freeze them and then drop them into your tank. If you have some weeks of extreme weather, it really does help.

The down low on D.O and Water Aeration

Understanding why you need to aerate is crucial. It maintains water temperatures and prevents stagnant water and things from overheating. In commercial growing, it also helps release some things from the water too, such as high levels of nitrogen gas. Another term you often hear in hydroponics, specifically aquaponics, is D.O.

D.O. is dissolved oxygen; it’s oxygen that is dissolved in the water and stays there. It’s crucial to plant development. If you have a high D.O. level, then it’s more suitable for healthy, happy plant growth.

Dissolved oxygen is measured in parts per million (ppm). The average city water and well water contains D.O. at very low levels of 4-8 ppm. In hydroponics, 7-10 ppm is usual. Anything less than that, and something is going on in the water that it’s not aerated enough, or there are factors that don’t allow for dissolved oxygen at the roots. Once you go to a higher ppm, you get some interesting effects on the water. Some growers who boost up to 20 plus ppm claim a 40% yield gain on a head of lettuce; this shows how critical it is for the plants to be able to take up D.O. The more oxygen in the water, the more efficient the nutrient uptake, and the more ion transfers happen between the roots and the water. You don’t necessarily have to get your D.O. up to 20ppm, but knowing that the levels are important is essential if you are growing hydroponically.

Increasing Dissolved Oxygen

Air stones and air pumps are the lowest cost and most common options. These will get you to levels of 7-8ppm.

You can also increase D.O. by dosing with hydrogen peroxide at safe levels (h202). When h202 sees carbon or organic material, it binds with it and breaks apart into 02 and H20—pulling the hydrogen off, becoming water and oxygen. The beauty of that is that much of that oxygen stays in the solution as dissolved oxygen, increasing levels to 10-12 ppm. However, hydrogen peroxide can be expensive and dangerous as it’s highly corrosive, so you need to prepare a safe working space.

In our research farm of 270 Hydroponic Towers, we use 2ml per liter of 5% peroxide weekly.

Then there are premium solutions where you can dial in to get the best levels of D.O. A Nano bubble generator (or, as it should be called according to the ISO standards, an ultrafine bubble generator) is one of these options. Nano bubbles are created by diffusing compressed oxygen into fast-flowing water, which further spreads and dissolves bubbles. Nano bubble generators have an oxygen transfer efficiency of up to 85 percent, nearly 30 times the rate of traditional aerators, and promote vigorous growth of crops in hydroponics. The problem with these systems is that they are expensive, so you would need to be able to justify the yield difference to spend that kind of money. They are very efficient, so it would be something to consider for a commercial system.

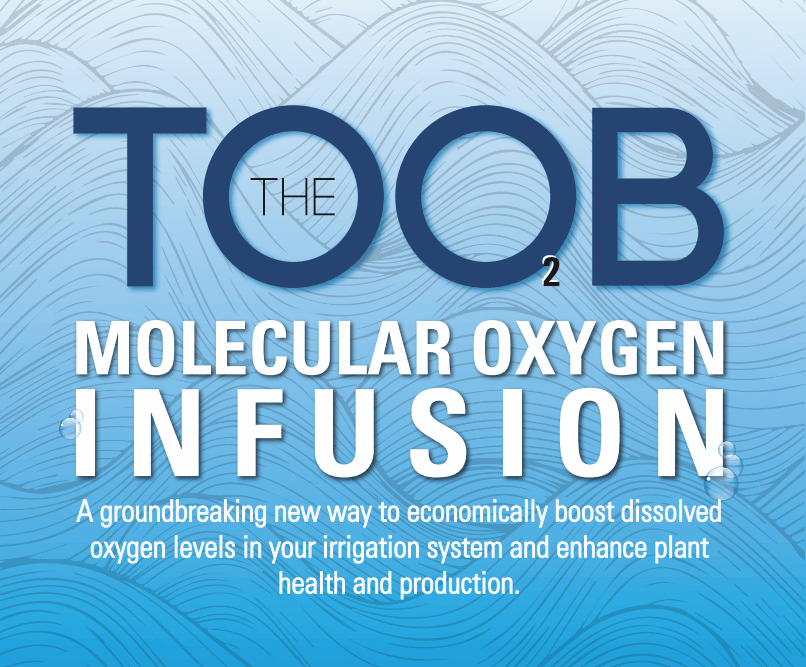

A recent and exciting option comes from a company BioTherm Solutions, with a system called the Toob, a Molecular Oxygen Infusion method that dissolves oxygen in water without making bubbles. As the water passes through the TOOB, it passes over the hollow oxygen-filled fibers, where it undergoes the oxygen infusion process. The grower manages the oxygen pressure—full details of how The Toob works are here.

What’s incredible about the Toob is that you can control the exact ppm of oxygen that you want. It’s relatively expensive compared to a Nanobubble generator.

Ozone generators are another option that disinfects water before it is used in a hydroponic system and gives more control over the pathogens and algae that are present. It’s safe in the sense of food, but it can be dangerous to use, so there are better systems for beginners.

Keeping it clean

We want to reuse as much water as possible, and water conservation is one of the significant benefits of hydroponics. We try to recycle as much as possible. Hydroponics uses approximately 95% less water than traditional agriculture because it is re-circulated. This water recycling makes it critical to maintain cleanliness to avoid algae and pathogens.

Some of the filtration systems we use to help with this are as basic as a disk/screen filter 100 microns or smaller; it will keep larger particles from entering the reservoir. They are cheap and straightforward to install. We also use UV filtration; they come in all shapes, sizes, and flow rates. When our water returns from feeding the plants, it comes back through a drain system, collects in the sump, and is pumped back to the main reservoir through the UV filter. It’s very effective in removing pathogens and bacteria before redosing the plants.

UV filters can remove the iron from your water, which can lead to iron deficiencies, so be aware of that.

In 2022 we partnered with California-based Current Culture H20. We are excited about their hypochlorous acid solutions, Clear Line (commercial), and UC Roots (home and hobby). Especially in drip systems where you will get a build-up of salts and biofilms that can lead to clogging, it is very effective in reducing mineral build-up, limiting algae growth, and allowing your drip emitters to flow more efficiently. All of this leads to less labor.

Hypochlorous (with a p) acid should not be confused with hydrochloric acid, which is highly corrosive and dangerous. Hypochlorous acid is a weak acid; the chlorine ion comes off, disinfects, and returns. In addition to disinfecting, it removes salts and nutrients that build up in systems over time. It keeps healthy roots that are beautiful and white, and we have seen tremendous success using these products.

If you are a commercial grower, really good maintenance and cleanliness of your hydroponic systems will lead to less overall labor, decreased operating costs, and higher yields.

Interested to learn more? You can listen to the full recording from our live “masterclass” on the importance of water quality on Food Growers United and the Clubhouse app, including a Q&A session where two of our in-house experts, Tyler Harbers and Sean Schaub, break down the basics.

Q&A session

01:00 – Capturing waste water from RO systems

01:04 – Hard water

01:05 – Filtration of water on the front end v’s back end

1:12 Crops and segmentation- zoning tanks

1:16 Compost tea and aeration

You may also like Basic Principle of Hydroponics from the same series on Food Growers United.